We Manufacture the Fastest Racing Components in the World!

Stage V Engineering has been purchased by For Hemis Only.

All Trademarks and Copyrights are solely owned by For Hemis Only.

Heads

Details

If you are building a NHRA blown alcohol car or Top Fuel car and are looking for Billet cylinder heads, call our friends at Brad Anderson Enterprises, or Alan Johnson Performance, or Ken Veney Industries.

Our intention is to supply a head for the racer that previously used our 1/2 solid Cast Aluminum water jacketed Hemi head. These race cars tend to be in the class of “Family Fun” drag racing. CIFCA would be a good example. In the past some of these racers used “trickle down” used billet heads from the pro teams. Our heads can use stainless valves which reduce the operating cost of racing.

The heads are even available for those who need the stock hemi exhaust flange and bolt pattern. The heads come fully CNC ported with seats and guides installed. Most automotive shops can perform the valve seat work.

Specifications

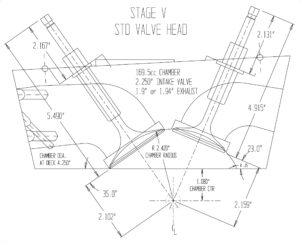

Std valve angle:

Int Valve Standard: 2.250″ x Exh Valve: 1.900″

Chamber Vol: 168 cc

We use a longer than stock intake valve to accomodate taller springs.

Options

Standard Stainess Valves only.

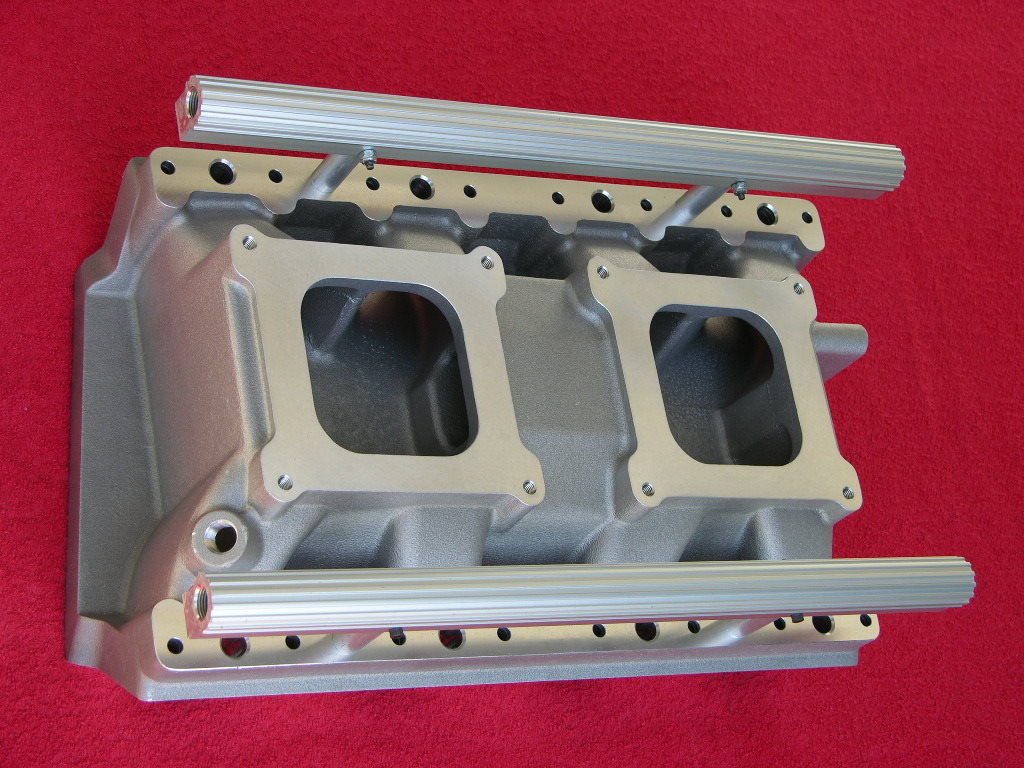

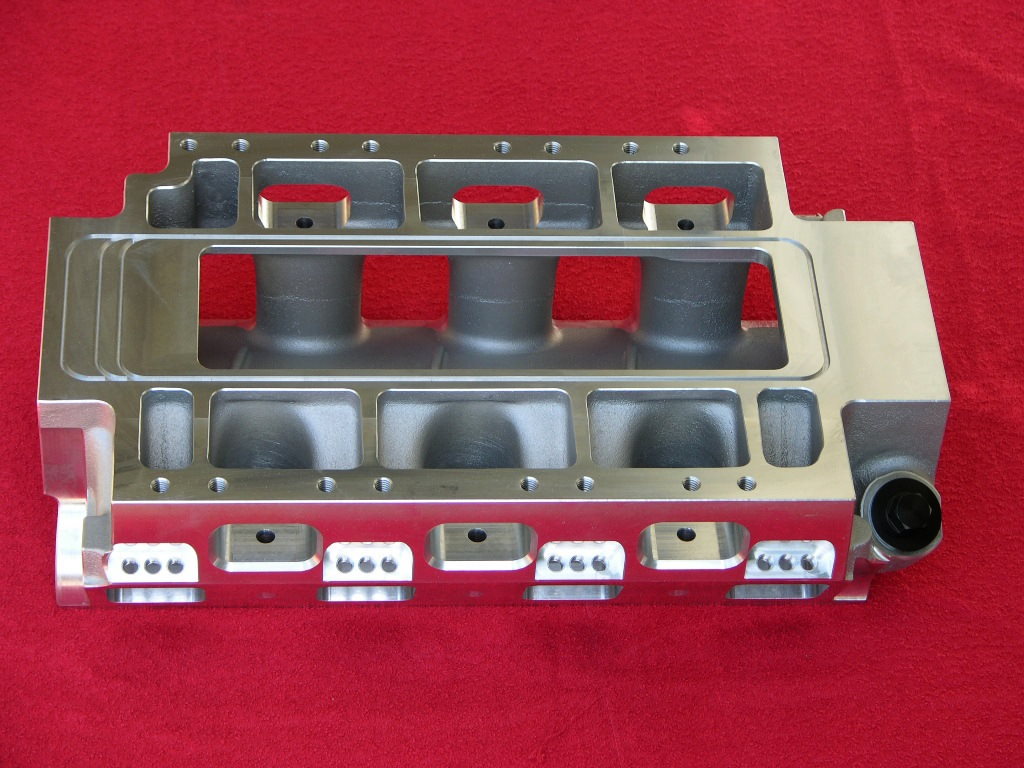

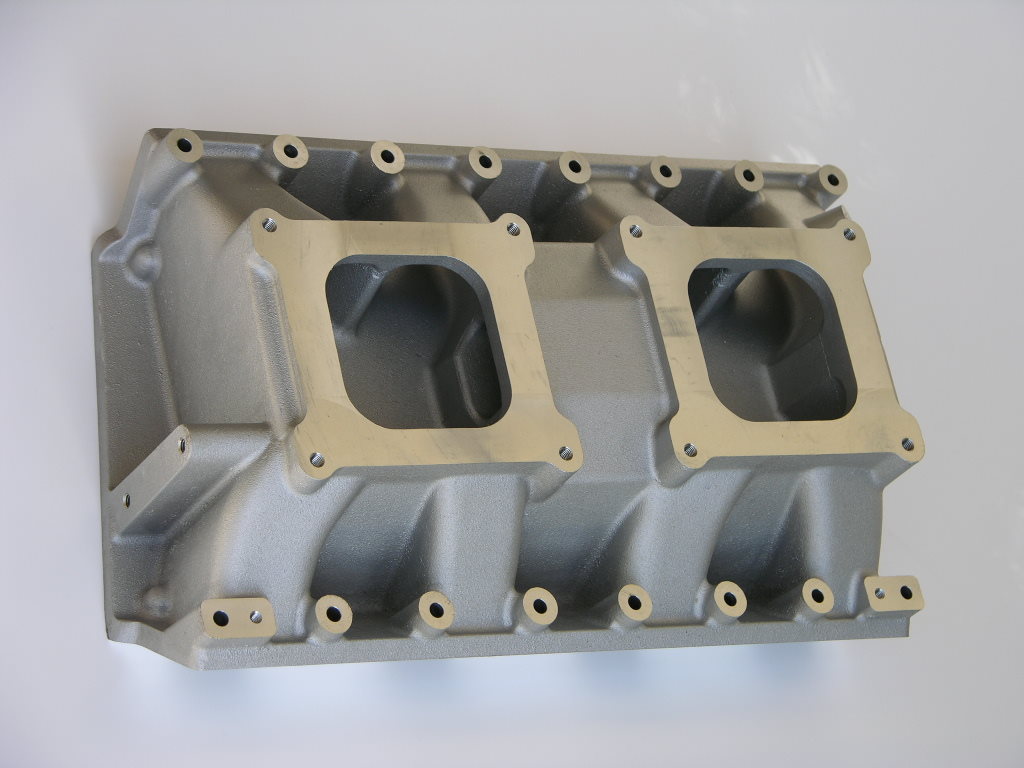

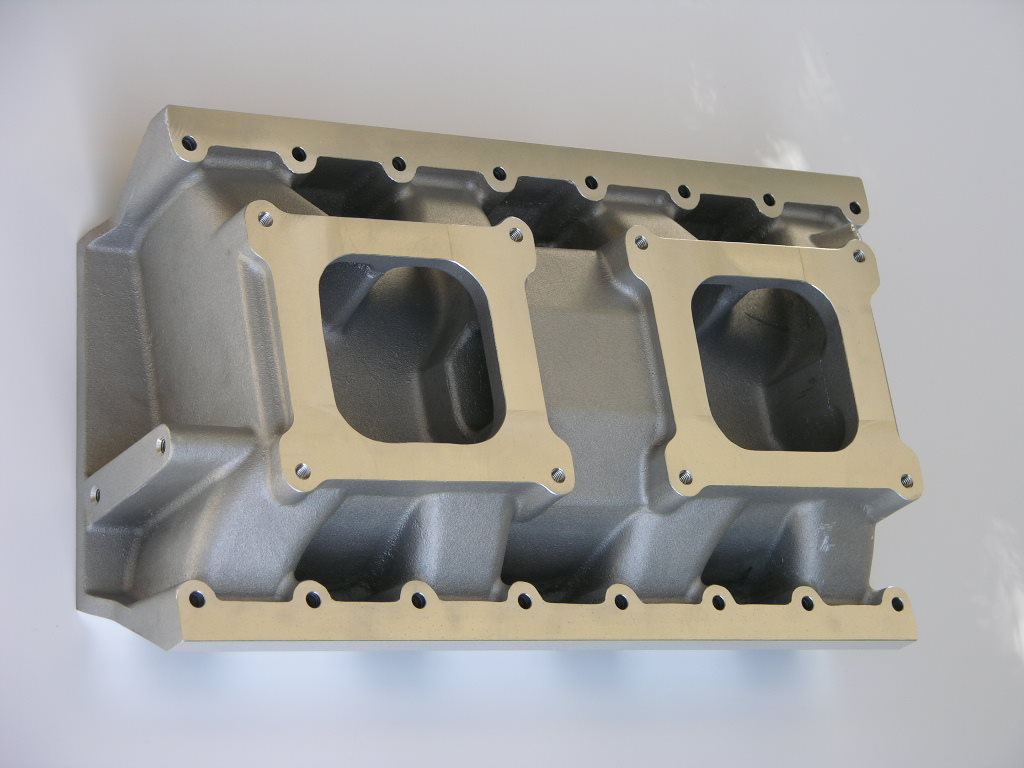

Standard 16-bolt or vertical 6-bolt intake manifold bolt pattern configuration.

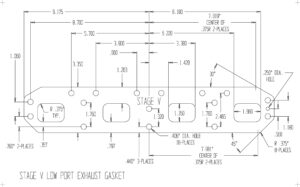

Stock low exh port or raised exh port.

Head bolt size, All drilled for 9/16″, 1/2″ Nutseats available.

Single or Dual spark plug versions.

Stainless steel exh guides and chrome-moly int guides are recommended.

Copper alloy valve seats available.

Details

These are the ultimate in water cooled Hemi cylinder head technology. The Stage V hemi head was developed under the rigors of Top Fuel racing for years and proven to survive several seasons at 6,000 Hp levels. Doubtful if any other hemi head manufactured today would even survive a burn-out. Despite having numerous strength/design advantages, with the factory look, Stage V heads can still be mistaken for the original iron version. Some of the other hemi heads currently produced look so little like the original, you might as well just install a chevy engine.

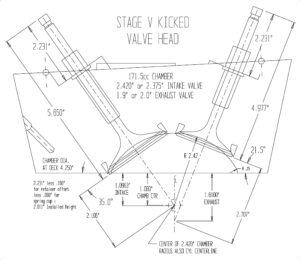

The standard valve angle head can be offered with smaller port sizes for increased velocities for normally aspirated engines. The big valve size “kicked valve” version is usually for large-CID or supercharged engines requiring massive port sizes. The heads have a wide variety of options such as the GM style intake bolt pattern which lends itself to fabricated manifolds. A “Half-Solid” version can be ordered for extreme power configurations or external water ends for twin-turbo endurance. An option of a “Smooth-End” setup for Custom Rods where you can have the dependability of a 426 and the “clean-looks” of a 392 early model.

If you are building a Hemi for Street-use, Bonneville, blown fuel boat drag racing, Pro Mod or virtually any application where water cooling is required the Stage V head has the most potential for your success. In fact, a set of these heads were on the “King of Speed” Al Teague\’s Speed-O-Motive Bonneville streamliner when it set the FIA world record for top speed by a wheel-driven vehicle 409-plus m.p.h. average with a 433 m.p.h. exit speed. That is full power for seven miles!

Specifications

Std valve angle:

Int Valve: 2.250″ x Exh Valve: 1.900″-1.940″

Chamber Vol: 168 cc

“Kicked” valve angle:

Int Valve: 2.420″ x Exh Valve: 1.900″-2.000″

Chamber Vol: 173 cc

Options

Stock or big valve versions.

Standard 16-bolt or vertical 6-bolt or 10-bolt GM style intake manifold pattern configuration, or 16 & 6 or GM & 6 patterns.

Stock low exh port or raised exh port.

Head bolt sizes 7/16″ stock, 1/2″, or 9/16″

Single or Dual spark plug versions.

For supercharged engines stainless steel exh guides and chrome-moly int guides are recommended.

Copper alloy valve seats available.

Details

These heads were designed for very competitive normally aspirated engines needing a smaller combustion chamber for higher compression ratios and lighter pistons. The valve angle has been “flattened out” to decrease the chamber size. The intake port runner has been raised considerably. The shafts and intake and exhaust rockers are the same as the big valve head but the rocker stands are M2000 head specific. The other part that is different are the 3/16″ longer spark plug tubes.

The smaller chamber coupled with the much longer intake port short turn seems to increase power level output by achieving a more complete burn with less lost during overlap. It is not uncommon to see a 200 Hp increase over a very competitive big valve standard chamber hemi.

The hemi is a large engine that is a tight fit in the engine compartment, so rather than raising the valve cover straight up we rotated it up 2 degrees leaving the exhaust side of the head unchanged. The exhaust valve can be standard hemi, but the intake valve is now longer to accommodate the raised runner.

All Millennium / M2000 heads have the external water option as they are generally used for serious all out racing.

Specifications

Int Valve: 2.420″ x Exh Valve: 1.900″

Chamber Vol: 149 cc “Flattened” valve angle

Options

Standard 16-bolt or vertical 6-bolt or 10-bolt GM style intake manifold pattern configuration, or 16 & 6 or GM & 6 patterns.

Raised exhaust port only. Head bolt sizes 1/2″, or 9/16″.

Single or Dual spark plug versions.

For Nitrous engines stainless steel exh guides and chrome-moly int guides are recommended.

Copper alloy valve seats available.

Valve Covers

Aluminum Single Plug Hemi Polished

Aluminum Single Plug Hemi Finned, Black Wrinkle Powdercoated

Aluminum Single Plug Hemi Dual Tube Black Wrinkle Powdercoated

Aluminum Single Plug Hemi Black Wrinkle Powdercoated

Option: a single stainless steel oil fill tube (as shown) can be installed to each cover for an additional fee.

Rockers Arms

Maximum Strength and Light Weight

Features

All Stage V intake and exhaust rocker arms are made from investment 17-4 stainless steel which has 190,000 psi tensile strength in all directions, which is better than billet steel that has only 180,000 psi tensile strength in the strongest direction and only 70% of that when load is applied 90 degrees to the grain flow. Stage V rockers have full strength in all directions making them significantly stronger than any competing rocker arm from any manufacturer.

All Stage V intake and exhaust rockers feature roller tips which reduce side loading forces on the valves. When stock scrubber-type rockers are used, friction between the rocker pad and valve tip preloads the valves to the extent that the valve heads do not seal on the seats immediately during compression. This allows cylinder pressure to bleed off and effectively increases cam duration, robbing power. Roller tips eliminate the problem while also reducing valve guide wear. All of our rocker arms feature carburized alloy steel rollers and carburized steel pins which are riveted in place. Since 1986, we have never had a roller or pin failure in any application from street to Top Fuel.

During the manufacturing process, we bore each rocker arm to a very precise #16 microfinish. This takes about ten times as long as the competition’s process. The result however is a very smooth bore which fully supports the bronze wear bushing after it is pressed into place. In competing rockers, the bores are left very rough causing the bronze bushings to quickly ooze into the irregular surface during engines operation. This compromises the precise fit between the rocker arm and rocker shaft leading to accelerated wear.

All Stage V rocker arms are equipped with pressed-in bronze bushings honed to a very precise +/-.0001 tolerance. All Stage V rocker arms are rough honed then finish honed in a three step process which ensures a true bore for a perfect fit on your motor.

Stage V intake rockers are available with optional ratios at no extra cost. The standard ratio is 1.6, with 1.7 being the alternative for those seeking an increase of .030 to .040 effective valve lift without switching cams.

All Stage V Hemi intake and exhaust rocker arms feature an attractive gray sandblast finish. The tops of the beam surfaces are polished to a mirror sheen and Stage V logos are either in engraved or raised and highlighted. Many customers comment that these parts are too nice to hide under a valve cover. This appearance treatment is standard on all Stage V rocker arms.

Stage V intake and exhaust rocker arms are the lightest yet strongest parts available from any source. Our radical new tubular Severe Duty ER-3TA and Top Fuel ER-6TF exhaust rockers are 30% lighter than the billet steel parts available from our closest competitor while strength is second to none.

The ER-6TF Top Fuel exhuast rocker arm comes standard with large 7/16″ adjuster holes for the extra measure of strength needed in Top Fuel drag racing applications. All other Stage V intake and exhaust rockers come standard with 3/8″ adjuster holes, although customers can specify an upgrade to 7/16″ adjuster holes.

All Stage V intake and exhaust rocker arms are completely rebuildable. In supercharged alcohol and fuel applications, tune-up mishaps and extreme loading can cause roller damage and accelerated bushing wear. This can be reversed quickly and economically by pressing out the old parts and replacing with new. Stock-type scrubber rocker arms on the other hand are much more expensive, if not impossible to repair if the tips are damaged.